Polymer lab

Polymer lab is equipped with modern facilities for the testing of LPG Equipments like Suraksha Hose and Consumables like RPVC Seals, Safety Caps, Rubber Soft parts etc. as per the following relevant standards:

-

Testing of Suraksha LPG Hose as per IS 9573:2017 (Part 2)

-

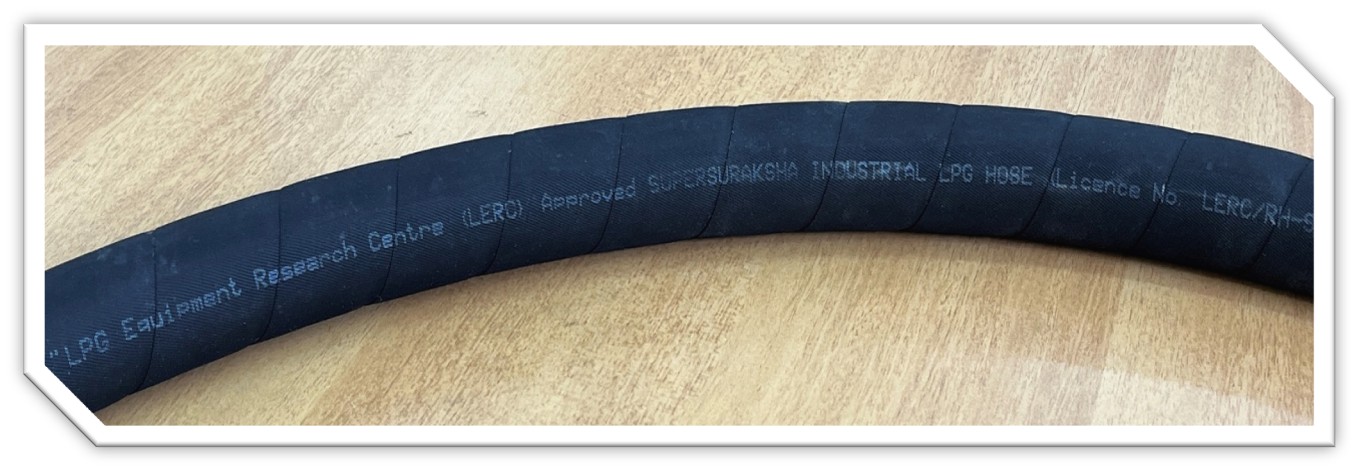

Testing of Super Suraksha Hose as per IS 9573:2017 (Part 1)

-

Testing of RPVC Seal as per ASTM E:1252 & Oil Industry Specifications

-

Testing of Safety Cap as per ASTM E:1252 & Oil Industry Specifications.

-

Testing of O-Rings as per ISO 4650:2012, IS 9573:2012 & Oil Industry Specifications

Testing Facilities

-

Digital Tensile Testing Machine

-

Ozone Chamber

-

Fourier Transformation Infrared Spectrometer

-

Humidity Chamber

-

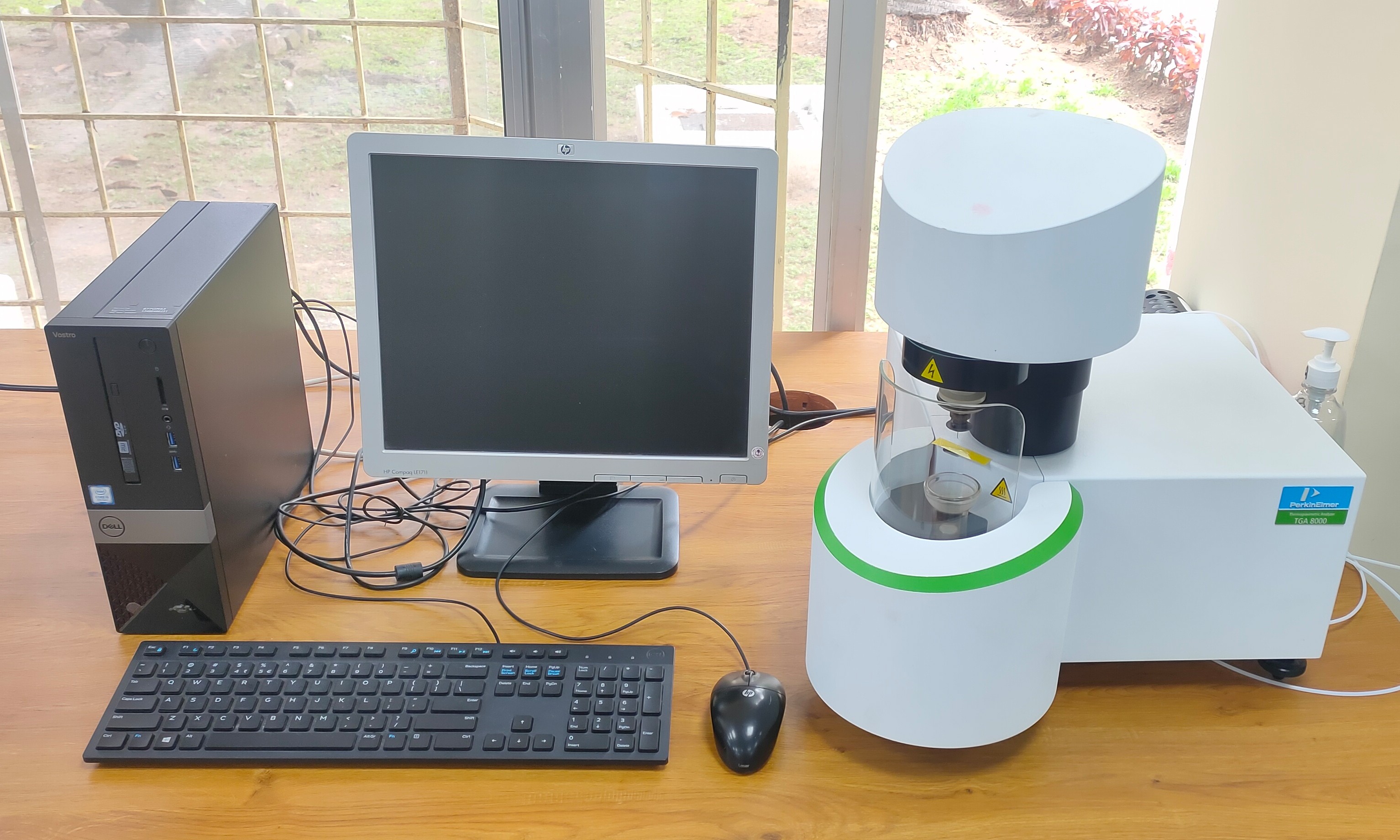

Thermal Gravimetric System

-

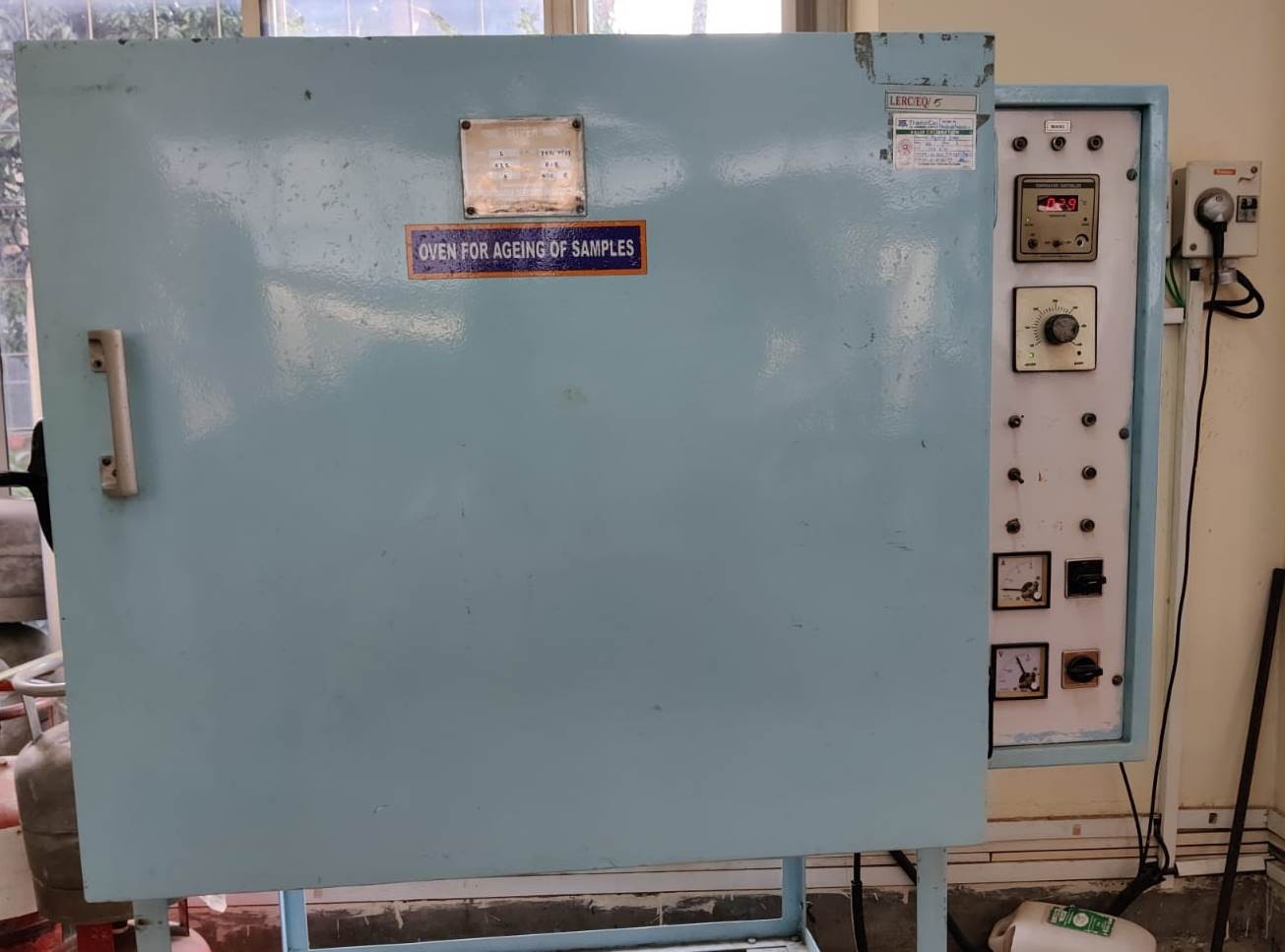

Ageing Oven

-

IRHD Wallace Hardness Tester

-

Video Measuring System

- Differential scanning Calorimeter

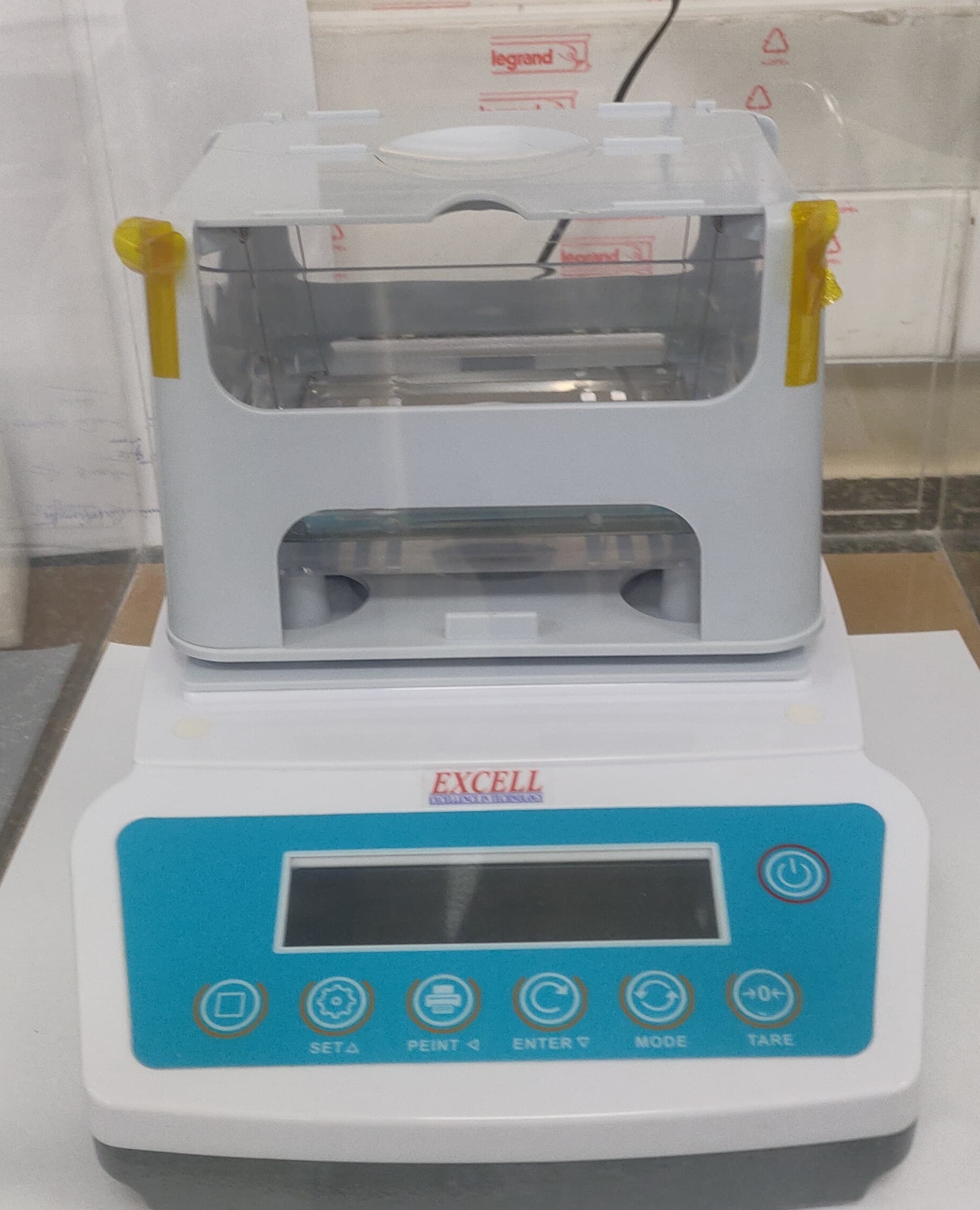

- Specific Gravity

Digital Tensile Testing Machine

Test Method – IS 3400:2012 Part I

Feature –

-

Variable frequency 2 -speed control

-

Digital load indication

-

Capacity – 5000 N

Application – For determining the tensile and elongation properties for rubber compounds

Ozone Chamber

Test Method – IS 9573:2012

Ozone Chamber covers the estimation of the resistance of vulcanized rubber to cracking when exposed to an atmosphere containing ozone. The rubber specimens are kept under a surface tensile strain, and the ozone content or partial pressure in the test chamber is maintained at a fixed value. It provides precise and accurate ozone (O3) concentration environment for rubber and polymer testing

Application – It is used to evaluate the ozone ageing resisting performance of Rubber.

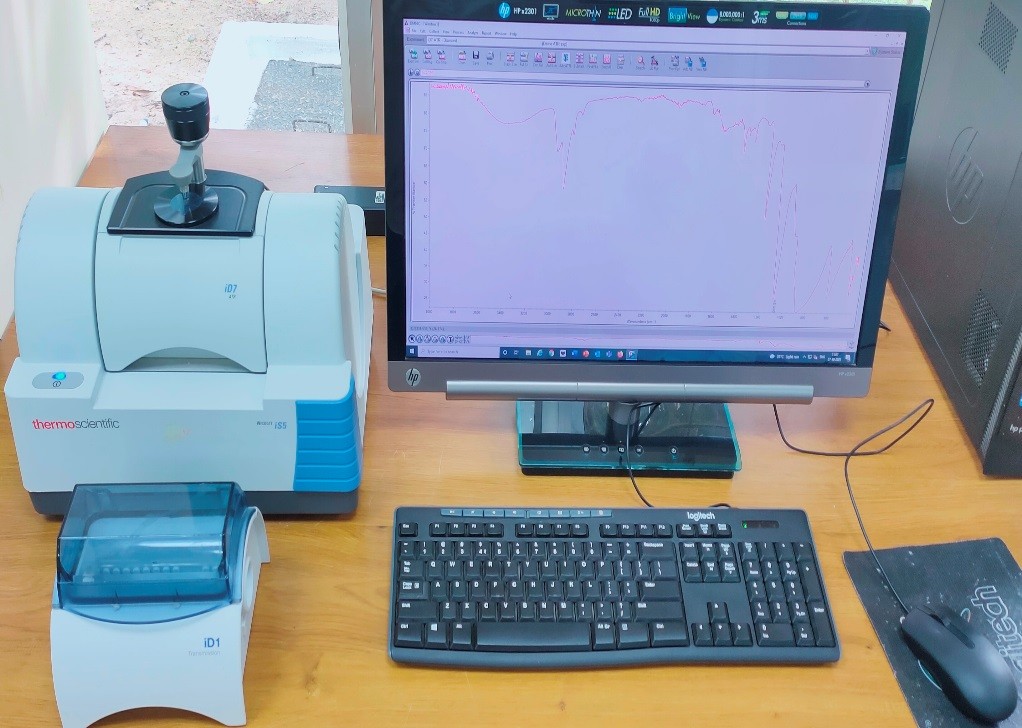

Fourier Transformation Infrared Spectrometer

Test method – ISO 4650:2012 (E)

Feature –

-

Real time, ratio-recording instrument with built in handling facilities

-

Continuous recording of infrared transmittance or absorbance of sample as a function of frequency to record spectra.

-

Minimum sample preparation required for testing.

Application – Qualitative identification and estimation of Compounds in polymer materials

Humidity Chamber

Test Method – IS 3400:2012 Part I

Feature –

-

Temperature upto 10 Deg C / 60 Deg C and humidity range 40% to 95% Rh

-

Microprocessor controller with LCD display and sensor for precise control of temperature and humidity.

-

Self-Diagnosis for errors

-

PC Compatible

Application – For conditioning of Rubber samples prior to testing

Super Suraksha Hose

The specific gravity of an object is the density of that object divided by the density of water.

| S/N | DESCRIPTION | DOWNLOAD |

|---|---|---|

| 1 | Polymer Lab Brochure | Click here to download |

The specific gravity of an object is the density of that object divided by the density of water.