Mechanical lab

Mechanical lab is equipped with modern sophisticated facilities for the testing of LPG Equipments like Cylinder, S C Valves and Domestic Pressure Regulators as per the following relevant standards:

- Testing of LPG Cylinders as per IS 3196:2013 Part I & IS 3196:2012 Part III

- Testing of SC Valves as per IS 8737:1995 (RA 2010)

- Testing of Domestic pressure regulator as per IS 9798:2013

- Testing of Liquid off – Take valve as per IS 16484: 2017

- Testing of Aluminum cylinders as per IS 17613: 2021.

- Testing of High-Pressure Regulators and Adaptors as per IS 16280:2021.

- Testing of LPG cylinders as per SASO ISO 22991: 2019.

- Testing of Pressure regulators as per SASO EN: 16129: 2013.

Testing Facilities

- Universal Testing Machine

- Spark Emission Spectrometer

- Automated Test Bench for Valve & Regulator

- Automated Test Facility for Burst test of cylinder

- Izod Impact Tester

- Laboratory Freezer

- Cyclic Corrosion Cabinet

- Optical Microscope for Metallurgical analysis

- Paint Testing Facilities for range 1µ to 200µ

- Gauges and Precision Measuring Instruments

- Digital hardness tester.

- Digital spring tester.

- In-House Workshop which has machines like Pillar drilling machine, Conventional Lathe Machine, Milling Machine, Surface Grinding Machine, Bandsaw Machine, Fly Press for various types of sample preparation for testing.

UNITEK Tensile Testing Machine with Electronic Extensometer

Test Method – IS 1608:2005(Reaffirmed 2011)

Feature –

- Range – 0 -100kN

Application : For determining the stress-strain properties of various metals.

Spark Emission Spectrometer

Test Method – ASTM 415 – 2008 / STM-Z01/ STM-B01

Feature –

- Elemental composition analysis for Fe, Zn, Cu & Al Bases.

Application: For carrying out chemical composition analysis of Fe, Zn, Cu & Al Bases.

Test Bench for Testing S C Valves and Regulators

Test Method – IS 9798:2013 & IS 8737:2010

Feature –

-

Automated test bench for testing in the range 0 – 17 kg/cm2

Application – For carrying out pneumatic, hydrostatic and life cycle tests for S C Valves and Domestic Pressure Regulators

Pressure Test Facility

st Method – IS 3196:2012 Part III

Feature –

-

State-of-the –art automated computerized testing system with safety trips and alarms

-

Range of Testing – 0.01 kg/cm2 – 200 kg/cm2

Application – For carrying out hydrostatic and burst pressure test of LPG Cylinders

Izod Impact Tester

Test Method – IS 1598:1977(Reaffirmed 2015)

Feature –

-

Range – 0 – 170 Joules / 2 Joules

-

Test piece is required to be in a form of a rod with a V-Notch.

Application – For determining the fracture toughness of metals.

Laboratory Freezer

Test Method – IS 9798:2013

Feature –

-

Automated laboratory Freezer with safety trips & alarms

-

Microprocessor controlled programmable with temperature upto -50 Deg C

-

Accurate temperature control and holdover capability.

-

PC compatible

Application – This instrument is used to assess the low temperature performance of metals and rubber components.

ASCOTT Cyclic Corrosion Test Cabinet

Test Method – IS 9844:1981(Reaffirmed 2015)

Test Method – IS 9844:1981(Reaffirmed 2015)

Feature –

-

Controlled Parameters – Temperature, Relative Humidity, Salt Fog

-

Designed to enable salt either salt fogging, humidification or air drying to be selected either manually or automatically for sequential / cyclic control.

-

Humidification Range – > 95%. Active dehumidification during air drying phase.

Application – This equipment is used to assess the general corrosion resistance of the coatings which is applied onto metals using salt spray which is generated in a chamber wherein the samples for testing is kept. It is sort of a accelerated corrosion test.

Liquid off take valve test bench

- Test bench for analyzing performance of the LOT valve.

- Test bench for analyzing soundness and performance of safety relief valve.

- In house developed prototype for testing flow capacity of Safety relief valve.

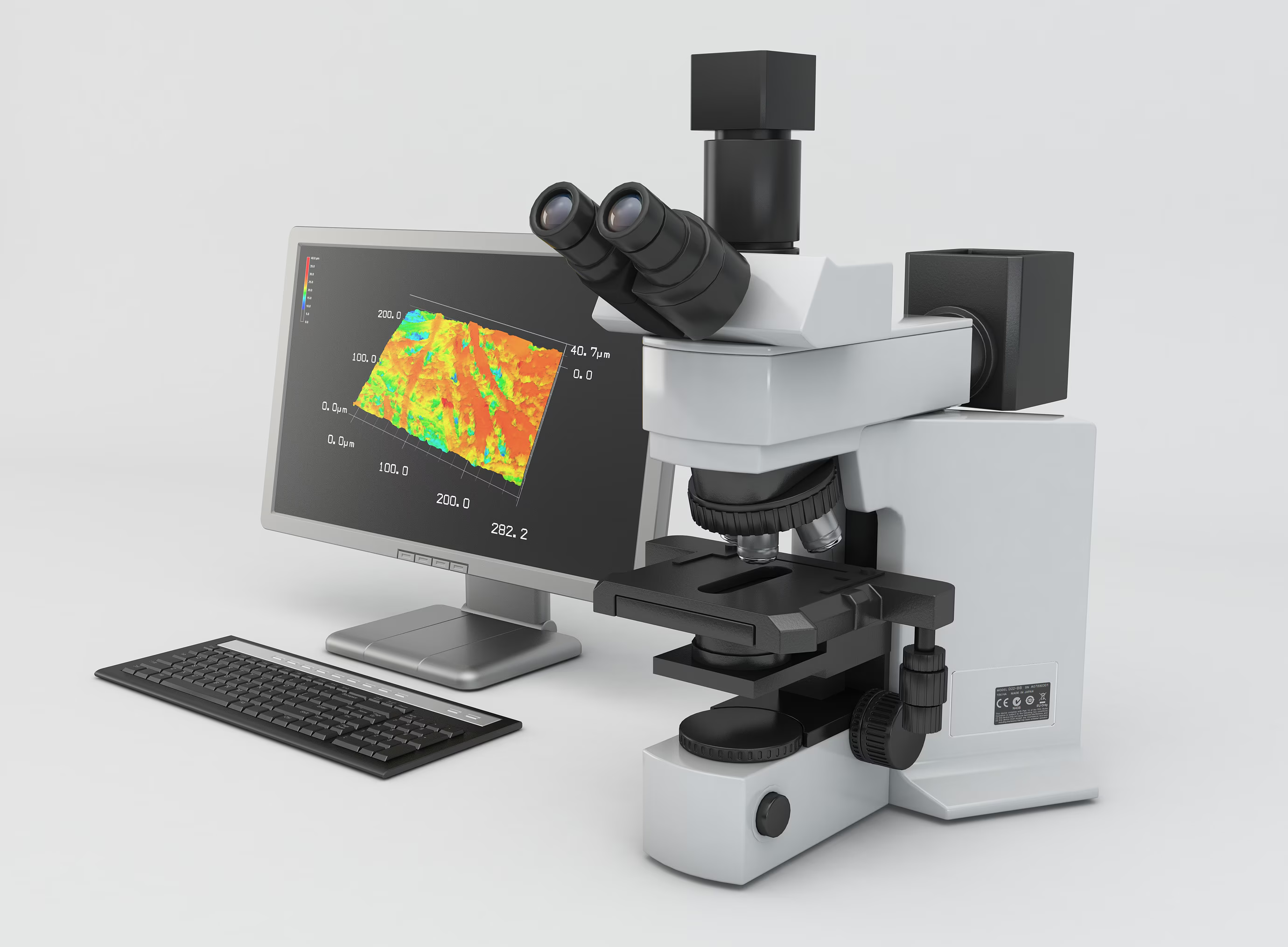

Optical Microscope for Metallurgical analysis

Application: For analyzing the metallurgical properties of metals, such as grain structure and other material characteristics.

Digital hardness tester

Application: For evaluating the hardness of materials using both Rockwell and Brinell hardness testing methods, providing comprehensive insights into material strength and durability.

Digital Spring tester

Application: For evaluating the load characteristics of the spring.

Impact Test for SC valve – Type test

An Impact Energy of 40J should be exerted on the valve by dropping a weight of 5 Kg mounted with a hardened steel ball of 13mm diameter intender and dropped from a height of 1m.

| S/N | DESCRIPTION | DOWNLOAD |

|---|---|---|

| 1 | Mechanical Lab Brochure | Click here to download |