Combustion lab

The Combustion Lab is equipped with state-of-the-art modern testing equipment for the evaluation of Domestic LPG Stoves, Commercial Burners, Portable Cooktops, Utility Flame Lighters, and Ethanol Cookstoves, in accordance with the following relevant standards.

Testing of Domestic PNG stove as per IS 17153:2019 & IS 5116:2020.

Testing of Commercial LPG Burner as per IS 14612:1999 & IS 5116:2020.

Testing of LPG Cooktop as per IS 11241:1985 & IS 5116:2020.

Testing of Utility Flame Lighters as per IS 22702:2018.

Testing of Portable stove as per EN 521:2019

Testing of Domestic LPG stove as per SASO 167:2018 & 168:2022.

Testing of Ethanol cook stove as per IS 18380:2023.

Testing of Portable Stove fitted with Butane Cartridge as per Draft IS Standards

Testing Facilities

-

Gas Soundness Test Workstation

-

Strength and Rigidity Test Rig

-

Gas Consumption Test Workstation

- Multi Parameter Test Bench including

-

Combustion Test

-

Resistance to Draught

-

Flame Temperature Test

-

Visual Tests

-

Ignition and Flame Travel Test

-

Flame Stability Test

-

Noise Control Test

-

Flashback Test

-

Formation of Soot Test

- Fire Hazard & Limiting Temperature Test Workstation

- Thermal Efficiency Test Workstation

As per OMC Specifications

Dimensional Analysis

Sheet Thickness Measurement of Stove Body, Spill Tray, Pan Support

Weight Measurements of various components like Gas Cock, Burners, Mixing Tube

Gas Soundness Test

Test Method – IS 4246:2002(Reaffirmed 2015) & IS 5116:2020

Feature –

-

Computerized system for measuring and recording the leak.

-

Accurate measurement of leak

-

Safety trips and alarms

Application – To check whether the gas carrying parts of the LPG domestic gas stoves and the complete assembly itself is sound against any gas leakage as per the requirement of the Indian Standard. soundness of the gas rail assembly is checked for any leakage by observing for appearance of bubbles in the bubble leak indicator placed in the air line.

Safety Test to check the soundness of the gas carrying parts of the LPG Stove against any gas leakage

Strength & Rigidity Test

Test Method – IS 4246:2002(Reaffirmed 2015)

Feature –

-

Computer aided test rig.

-

Automated loading of required weight on the LPG Stoves for deflection measurement.

-

Use of precision measuring instruments for measuring deflection.

-

Safety trips and alarms

Application – To determine the strength of LPG Stoves to resist getting deformed when loaded with heavy cooking utensils by measuring the vertical deflection of the top surface and the distance between opposite sides of the LPG Stove when loaded.

Checks the strength of the LPG Stove to resist deformation when loaded with heavy cooking utensils.

Vertical Deflection – 2 mm

Lengthwise Deflection – 5 mm

Breadthwise Deflection – 5 mm

Thermal Shock Test Chamber

- The burners are operated simultaneously at full rate for 30 min and the burners are shut-off.

- A quantity of 1.0 l to 1.1 l of cold water having a temp. of 15°C ± 5°C is poured steadily and uniformly over the glass top of the gas stove.

- One minute later all excess water is removed and the surface wiped dry.

The glass surface is checked for any breakage or cracks.

Gas Consumption Test

Test Method – IS 4246:2002(Reaffirmed 2015)

Feature –

-

Computerized system for measuring and recording the consumption of burners

-

Use of sophisticated and accurate flow meter for flow measurement

-

Precision control of required inlet pressure

-

Safety trips and alarms

Application – To verify whether the burner assembly of the LPG domestic gas stove gives the gas consumption rate as specified by the manufacturer of the stove within a range of + 8%. The gas consumption of each of the burners is calculated by volumetric method.

Multi Parameter Test Bench – Combustion Test

Test Method – IS 4246:2002(Reaffirmed 2015)

Feature –

-

Computerized system for measuring and recording the toxic level of flue gas emission.

-

Direct measurement of CO & CO2 content using infrared principle.

-

Measurement of Combustion Efficiency of LPG Stove.

-

Safety trips and alarms

Application – To analyse the flue gas which are the products of Combustion to determine the Carbon Dioxide (CO2) and Carbon monoxide (CO) content. The CO / CO2 ratio is determined by direct analysis of the flue gas, using an infrared flue gas analyzer

Determination of CO/CO2 ratio of Flue Gas (0.02)

Resistance to Draught

Test Method – IS 4246:2002(Reaffirmed 2015)

Feature –

-

Computerized system for measuring and recording the results

-

Wind conditions are simulated using computer control and variable frequency drive for fan operation

-

Wind conditions measured using precision rotating vane anemometer.

-

Safety trips and alarms

Application – To measure the performance of LPG Stoves by observing the flame of the burner operating at maximum consumption when the same is placed in a localized air current of 2 m/s.

Flame Temperature Test

Test Method – IS 4246:2002(Reaffirmed 2015)

Feature –

-

Computerized system for measuring and recording the results

-

Direct temperature measurement using digital temperature recording device.

-

Accurate height control for precise temperature measurement.

-

Safety trips and alarms

Application – To ascertain whether the flame temperature meets the standard requirement as stipulated in Indian Standard. The flame temperature of both the burner is measured at fully “ON” condition of the burner using a thermocouple at any point on a plane a specified height.

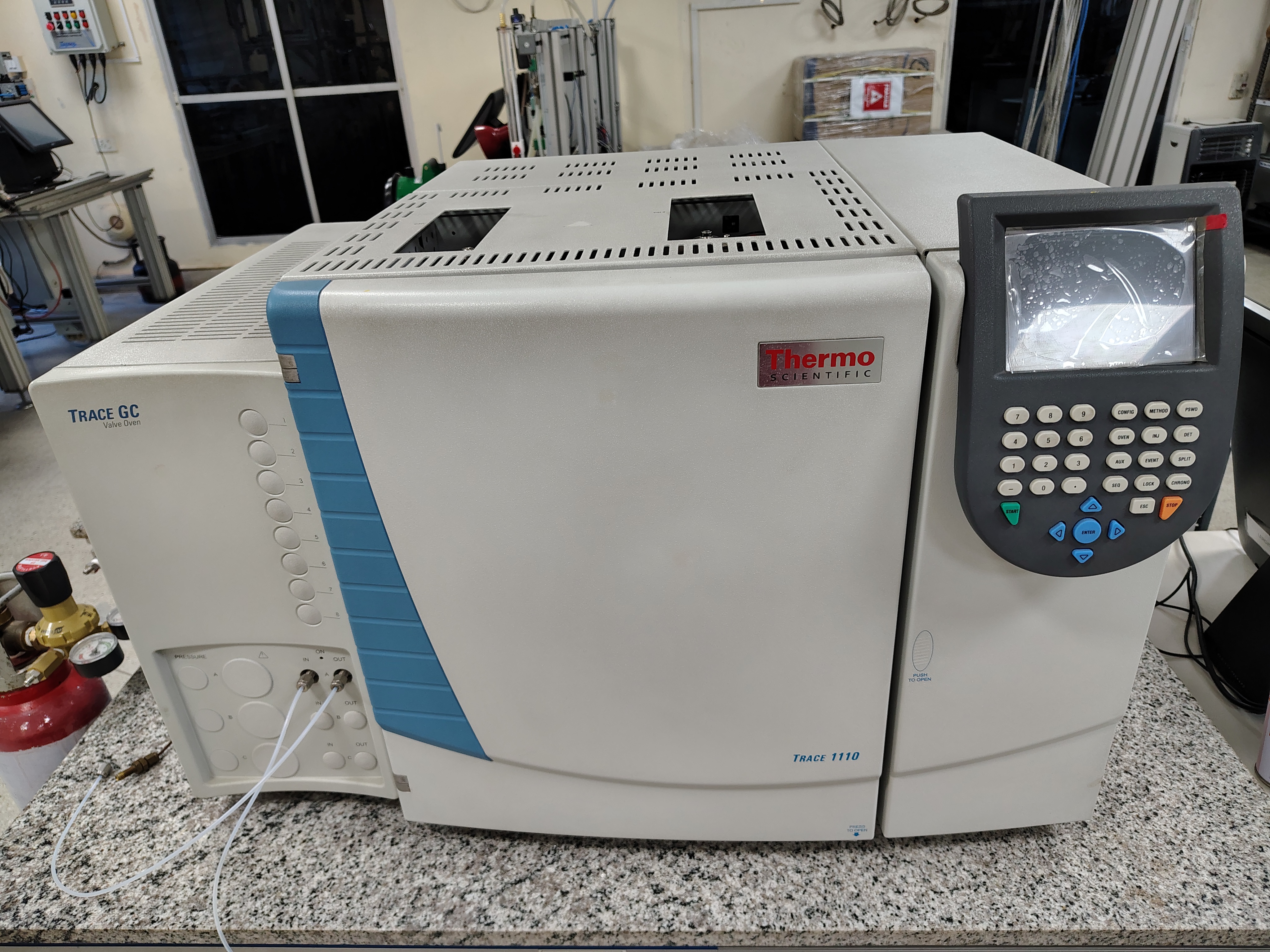

Gas Chromotograph

An analytical instrument used to separate, identify, and quantify volatile compounds in a gas or liquid sample. It works by passing the sample through a column, where the components in the sample are separated based on their interactions with the column’s stationary phase and their differing physical properties.

Fire Hazard and Limiting Temperature Test

Test Method – IS 4246:2002(Reaffirmed 2015) & IS 5116:2020

Feature –

-

Computerized system for measuring and recording the surrounding temperature rise when LPG Stoves are in operation.

-

60 nos. of thermocouples for temperature measurement

-

Automated panel movement for measuring ceiling temperature.

-

Non-contact IR thermometer for accurate recording of LPG Stove body and knob temperature.

-

Safety trips and alarms

Application – To check whether the wall, floor and ceiling temperatures at the most affected junctions while operating the LPG domestic gas stove meets the standard requirement when LPG Stove is placed in an enclosure mounted with thermocouples.

Test equipment for measuring the surrounding temperature rise when the LPG Stove is in operation

Wall (Side & Back) , Floor and Ceiling Temperature – Not exceeding 65°C above RT

Surface Temperature (other than working surface) – Not exceeding 120°C

Temperature of the Tap Handles – Not exceeding 60°C

Flame Temperature – Not exceeding 500°C at a height of H+20 mm from pan support top

Thermal Efficiency Test

Test Method – IS 4246:2002(Reaffirmed 2015) & LERC defined standard C-101

Feature –

-

Computerized system for measuring and recording the various parameter while carrying out the test and reporting of test results.

-

Electronic temperature measurement device for accurate temperature measurement.

-

Realistic determination of calorific value of the LPG used for the test by using a Gas Chromatograph.

-

Using an online weighing method for measuring LPG consumption during the test for more accurate and realistic thermal efficiency value for the stove.

-

Improved measurement uncertainty

-

Improvised event driven test facility to reduce human intervention during the test so as to eliminate the errors while testing to the extent possible

-

Safety trips and alarms

Application – A computerized thermal efficiency test set up for determining the thermal efficiency of domestic LPG Stoves and confirming whether it meets the standard requirement of minimum 68% . High Thermal Efficiency 74% Min.

Performance test of LPG Stove

Measures the fuel efficiency of the LPG Stove

Efficiency measured by Water Boiling Test

Efficiency calculated by measuring the gas consumption and rise in temperature of fixed quantity of water in the vessel from the room temperature to 90°C + 1°C

Testing of Portable Cooktop as per IS 11241

Testing of Portable Cooktop for Thermal Efficiency , Gas Soundness , Resistant to Draught , Combustion , Flame Stability , Ignition & Flame Travel tests as per IS 11241 Standards.

Testing of Ethanol Cook Stove as per IS 18380:2023

Testing of Ethanol Cookstove for Thermal Efficiency , Gas Soundness , Gas Consumption , Strength & Rigidity , Surface Temperature Tests . Resistant to Draught , Combustion , Flame Stability , Ignition & Flame Travel tests as per IS 18380 Standards.

Testing of Utility Flame Lighters as per IS 22702:2018

Testing of Utility Flame Lighters for Burning Behaviour , Flame Generation , Flame Height , Flame extinction , Refilling as per IS 18380 Standards.

Testing of Portable Stove fitted with Butane Cartridge as per Draft IS Standards

Full fledged testing of Portable Cooktop fitted with Butane Cartridge including Pressure testing and Leakage Testing of the stove , Thermal efficiency , Vibration & Drop Tests , Gas Consumption , Corrosion resistance Tests, Combustion Test as per IS standards.

Commercial Burner

Commercial Burners – M Type, G Type, T Type.

Only Thermal Efficiency Testing Facility is available as per IS 14612:1999.

Full fledged Testing Facilities for Testing PNG Stoves

Test Method – IS 17153 : 2019 & LERC defined standard C-101

Feature –

-

Computerized system for measuring and recording the various parameter while carrying out the test and reporting of test results.

-

Electronic temperature measurement device for accurate temperature measurement.

-

Realistic determination of calorific value of the PNG used for the test by using a Gas Chromatograph.

-

Using an online weighing method for measuring PNG consumption during the test for more accurate and realistic thermal efficiency value for the stove.

-

Improved measurement uncertainty

-

Improvised event driven test facility to reduce human intervention during the test so as to eliminate the errors while testing to the extent possible

-

Safety trips and alarms

Application – A computerized thermal efficiency test set up for determining the thermal efficiency of domestic PNG Stoves and confirming whether it meets the standard requirement.

Performance test of PNG Stove

Testing for PNG stove as per IS standard 17153

Measures the fuel efficiency of the PNG Stove

Efficiency measured by Water Boiling Test

Efficiency calculated by measuring the gas consumption and rise in temperature of fixed quantity of water in the vessel from the room temperature to 90°C + 1°C

| S/N | DESCRIPTION | DOWNLOAD |

|---|---|---|

| 1 | Combustion Lab Brochure | Click here to download |